Have any question? Call Us Now!!

Rotary screw compressors

Our energy-saving Air complete solution

➤ you can meet virtually any compressed air demand with fluid-injected rotary screw compressors from Kaeser. We offer a huge selection of compressors ranging from 2.2 kW right up to 315 kW.

➤ With efficient IE3/IE4 motors

➤ Intake capacity: 0.34 to 83.40 m³/min – 99 % final vacuum

Keep up the pressure

- Rotary screw compressors supply production processes in industry, trade and workshop applications with a reliable supply of quality compressed air. They are the preferred choice for users requiring constant pressure over prolonged periods.

- To ensure that our rotary screw compressors operate as efficiently as possible, we developed our own special rotor profile. Our SIGMA profile rotors provide you with energy savings of up to 15 % compared with conventional rotor profile designs.

- Furthermore, our airends with SIGMA profile rotors boast an exceptionally long service life. This is in no small part due to the roller bearings we choose to use: they are precision adjusted and generously sized. Combine this with our in-house high-end manufacturing processes with lowest possible manufacturing tolerances and you have an exceptional product.

Your Advantages

- Extremely efficient:

IE3 motors are mandatory in the EU since 2015. These motors and the SIGMA profile ensure that our packages use significantly less power. - Low-maintenance and service-friendly:

Cooling air filter mats protect the interior from dirt, the gas ballast provides enhanced water vapour tolerance, low speeds extend the service life of all components.

Wide opening doors and a removable rear panel facilitate maintenance.

Our vacuum screw solutions in detail

Vacuum airend

- Rotary screw vacuum airend with energy-saving SIGMA profile

- V-belt Drive

- Automatic belt tensioning

- Inlet valve controlled by a solenoid valve

- Cooling oil pump (gear pump)

- Permissible inlet air temperature up to +45 °C

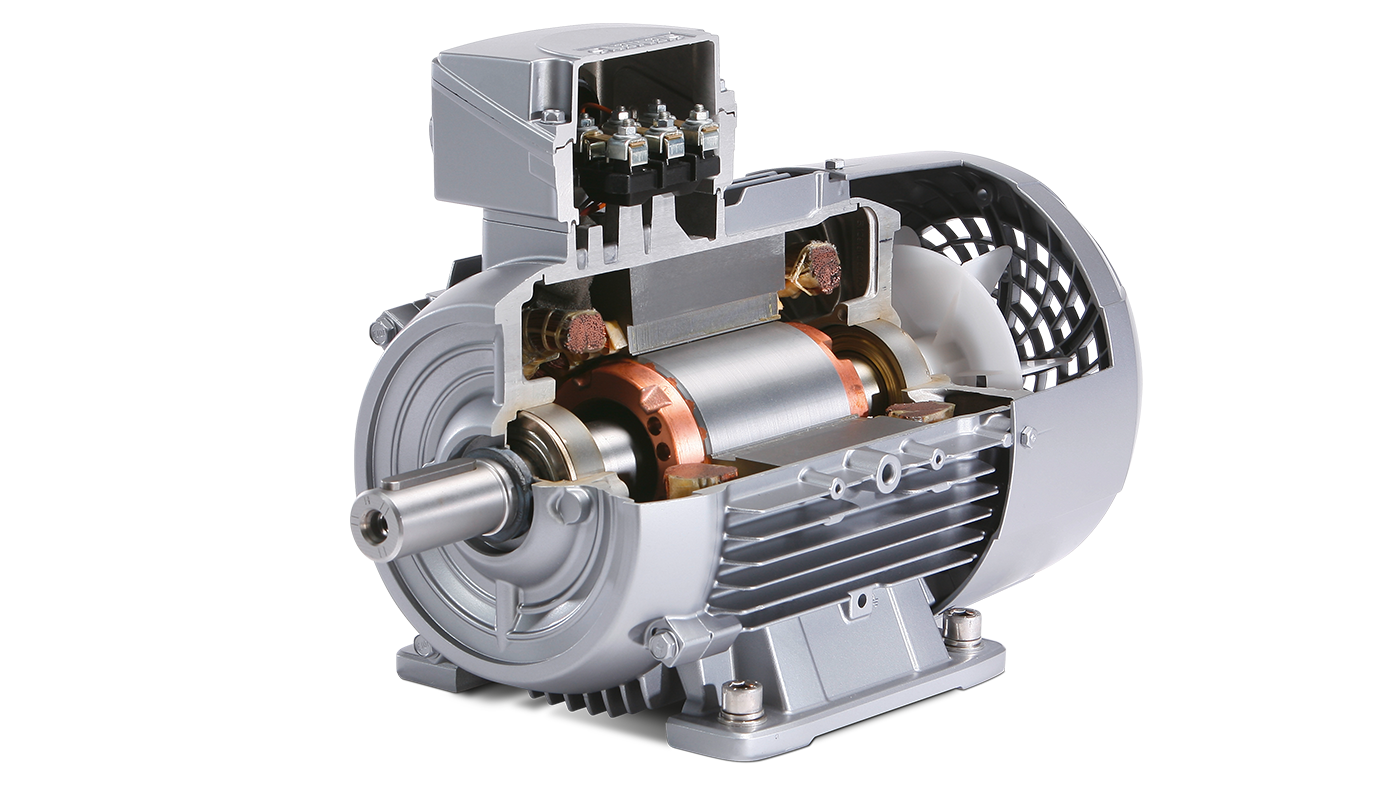

Electric motor

- Premium Efficiency IE3

- Degree of protection IP 55 (ASV series: IP 54)

- Insulation class F

- 400 V, 3-phase, 50 Hz

Cooling

- Air-cooled aluminium fluid cooler

- Designed for ambient temperatures up to +40°C

Cooling fluid circuit

- Thermostatic valve

- Bypass of full-flow micro-filter with replaceable insert

- Combined fluid reservoir and separator tank with pressure relief valve

- Multi-stage separator cartridge

- Fluid level sight glass drain valve and hose

- Quick-release couplings for measuring pressure differential

- Separator cartridge

Control cabinet

- IP 54

- 230 V control voltage

- Direct motor start-up

- Motor overload protection relay

General design

- Compact enclosure mounted on a solid base frame equipped with anti-vibration mounts

- Powder-coated surfaces

- Mineral wool soundproof lining

- Access doors on top and side

- Replaceable cooling air filter

- Airend and motor on anti-vibration mounts

- Flexible piping

- Fully guarded belt drive and fan

- Vacuum filter with pressure transducer to indicate clogging

- Infinite control of inlet valve opening via partial-load controller

- Changeover to Dual control mode possible

- Gas ballast unit for enhanced water vapour tolerance

Sigma Control

- "Traffic-light" LED indicators show operational status at a glance

- Plain text display

- 30 selectable languages

- Soft-touch keys with icons

- Fully automated monitoring and control

- Selection of Dual, Quadro, Vario and Continuous control as standard

- Interfaces: Ethernet

- Additional optional communications modules for: Profibus DP, Modbus, Profinet and DeviceNet

- SD-card slot for data-logging and updates

- RFID reader

- Web server

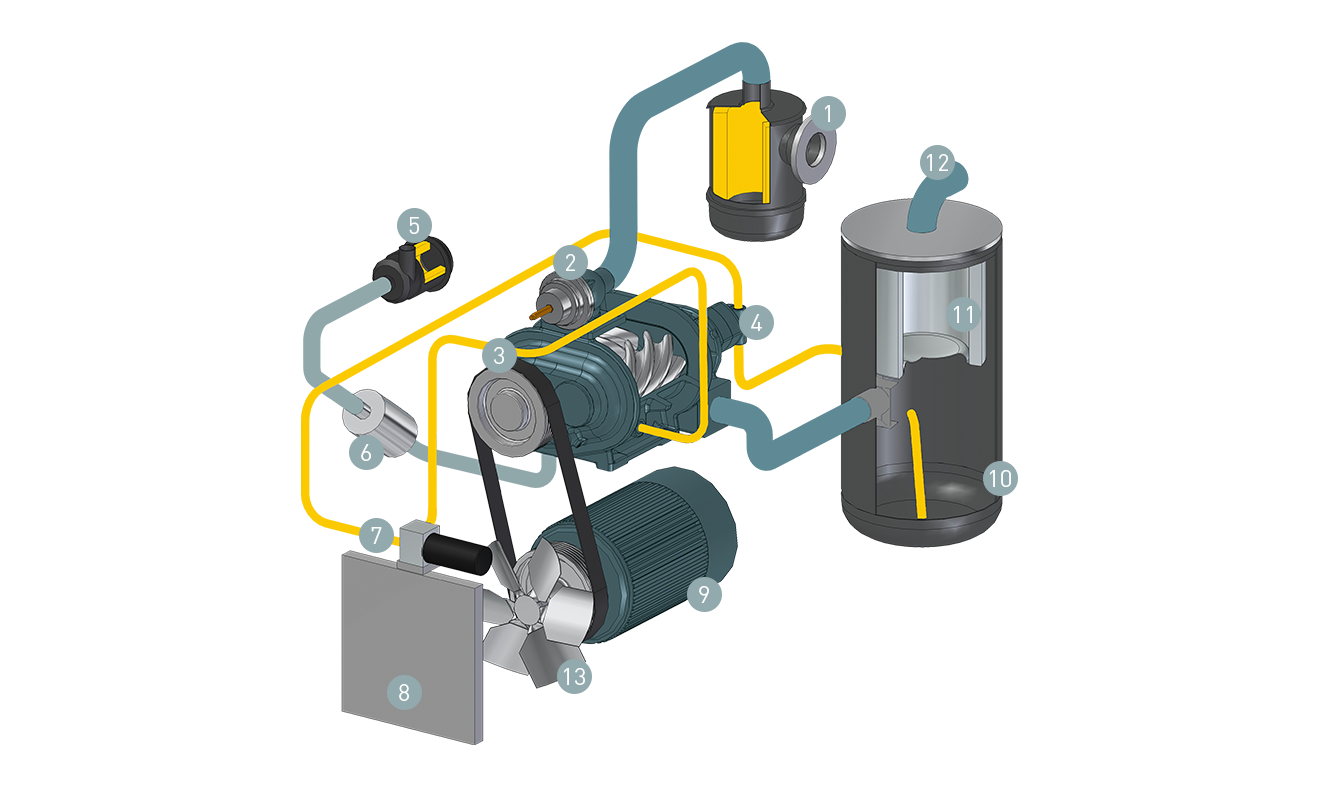

- Inlet filter

- Inlet valve (vacuum regulator)

- Airend

- Cooling oil pump (gear pump)

- Gas ballast air filter

- Gas ballast silencer

- Thermostatic valve with oil filter

- Oil cooler

- Drive motor

- Oil separator tank

- Oil separator cartridge

- Exhaust air

- Fan

The technical specifications can be found in this brochure:

Rotary screw compressors with fluid cooling

Large selection – Low life-cycle costs

- Fluid-injected rotary screw compressors are used in a wide range of sectors. They are highly durable and operate reliably and efficiently even at high temperatures of up to 45 °C. The associated investment costs are comparatively low.

- However, the lion‘s share of life-cycle costs is spent on energy (up to 80 %). in fact, energy costs taken over the lifetime of a compressor, add up to a multiple of investment costs. For this reason, Kaeser rotary screw compressors are equipped with energy-saving SIGMA profile airend rotors that save up to 15 % energy compared to conventional rotor profile designs.

Compressed air stations

With belt drive

With 1:1 direct drive

With two compressor units

Compressors for oil-free compressed air

Robust and clean-running for sensitive processes

- Whether for the semiconductor, food or automotive industries: our two-stage, oil-free compression rotary screw compressors tirelessly prove that process-sure purity and efficiency do indeed go hand in hand – even in extreme conditions.

- Uncompromising efficiency – Efficient compression with "Ultracoat"

- Service-friendly design – Maximum machine availability, minimal inspection time

- Have special requirements? With their variable interfaces, our compressors are easily integrated into existing compressed air and control systems. Our experts will propose a solution that is specifically tailored to meet your exact needs – just contact us!

With air-cooling

With water-cooling

With integrated compressed air dryer

Portable oil-free compression up to 45.8 m³/min

Turnkey solutions: KAESER Screw Air packages

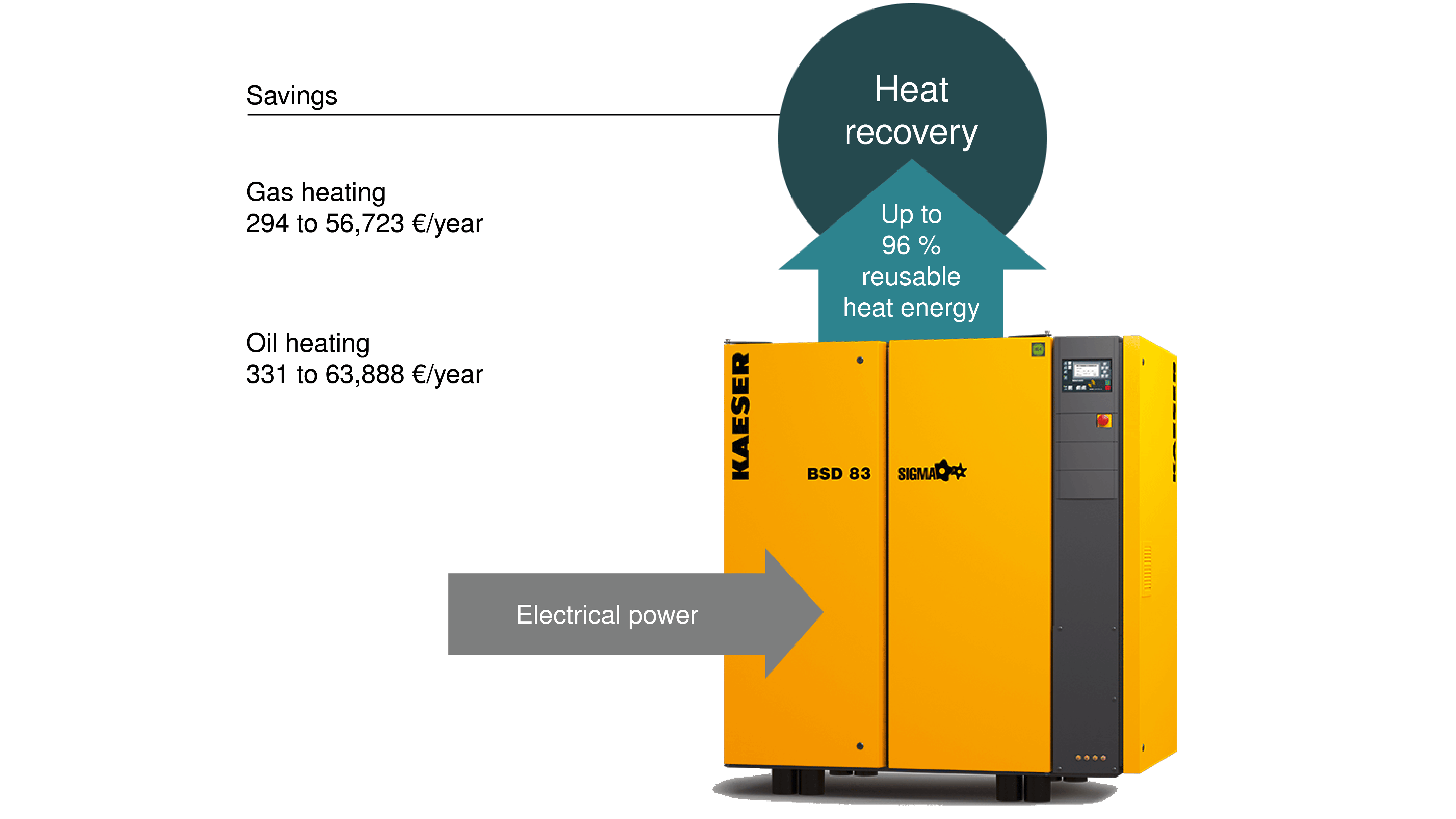

Heat recovery

Heat recovery : Save up to 96 % energy!

- A rotary screw compressor converts 100 % of the drawn electrical energy into heat. Up to 96 % of this energy can be recovered.

- The fully-enclosed design of modern rotary screw compressors makes them especially suitable for heat recovery. This fact applies to both fluid-injected as well as to oil-free compressors.

Heat recovery Solution